We’re always seeking to refine our processes here at the shop. If we can find a way to make a job more accurate and faster, then we’ll do it.

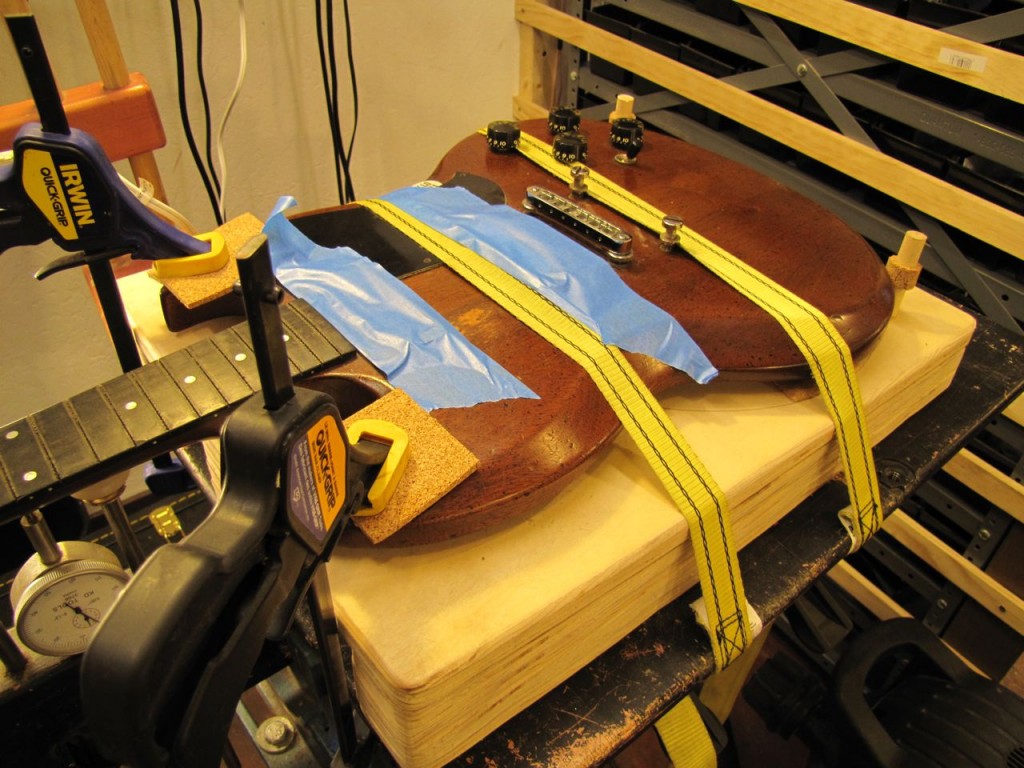

One of our latest ideas is to build specialized cauls for our neck jig (dubbed the “Fretty 5000”), which speed up the process of fretwork immensely. We’ve built a surrogate body for bolt on necks (which means your guitar body stays safely in the case while we’re working on the neck), and we’ve built specialized templates for Gibson solid bodies (Les Paul, SGs, etc), thin hollow bodies (ES335s and the like), and Dreadnaught acoustic guitars. These platforms are angled so that the guitar neck is perfectly level with the neck jig, ensuring greater accuracy while saving precious time. Commercially available neck jigs use threaded feet to set the body in the proper position, which can take a long time to set up.

Our cauls also support the body of the guitar properly while it’s strapped in to the neck jig. Since most commercially available neck jigs only support the guitars from the four outermost corners of the body, the guitar is strapped so firmly into the jig, they put unnecessary pressure on the instrument. Our cauls spread the pressure out across the entire body of the guitar, which can prevent possible damage. It also give the guitar a more solid base, so that the guitar doesn’t shake or shimmy while it’s being worked on. Faster AND more accurate = success!

Here’s our man Aaron whipping up a caul for hollow bodies:

A completed Les Paul/SG caul:

On the neck jig:

Here’s an SG strapped in for a re-fret:

The neck jig in action: