White Line Fever

by Geoff Luttrell

One of my favorite things about being a luthier is the wide range of skills and tools that I use in my craft. In my mind, guitars and basses are composed of three main sections—metal parts, wood parts and electronics—and each of these sections require a different set of tools and a different way of solving problems.

For years I believed that the best way to solve most problems on a guitar was through the use of a skilled hand, trained eye and a sharp blade. As time passed, and my scope of work broadened, I learned that a good power tool can solve problems that are almost impossible to tackle by hand, and in some cases can work miracles.

Case in point—How do you line a fretless bass neck that has dot markers right at the fret position without filling and moving the dots? Yeah, it’s a tough one.

My customer brought me this beautiful Roscoe fretless with a Dymondwood fingerboard and was on the verge of selling it as he just couldn’t deal with the unlined board. He needed to see the positions, and the side dots weren’t working for him. We discussed options, and decided that lining the board using the Plek‘s fret slotting function would be the only way to go. The slots, which would be inlaid with white plastic, needed to stay within the edges of the fingerboard, otherwise they would cut through the side dots.

The Plek has a “pocketed” fret slotting function which accomplishes exactly that. It uses a tiny end mill to cut fret slots to a programmed depth, width and scale. Only problem with this is that the Plek’s extremely accurate fret layout may not line up exactly with the side dots, which would leave the slot/dot relationship looking sloppy.

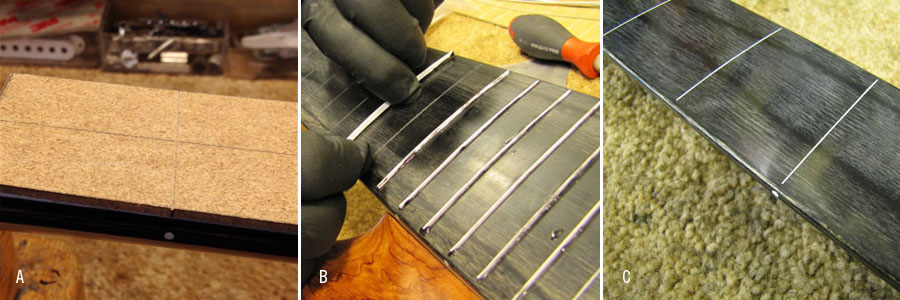

To determine the best scale length to use, I cut a dummy fingerboard out of some hardboard scrap and made a few test cuts (A). It took three tries, but I got all the slots and dots to line up nicely. I then cut the slots into the board and cut and inlaid all the little plastic strips into the slots (B). After the strips were in, I knocked them down with a sharp chisel, then sanded the board out to 2500 grit and buffed it to a mirror gloss (C). It looks beautiful, and I can’t think of a practical way to accomplish this with hand tools. You could rig a moveable block and then use a dremel router to cut them one by one, but it would take all day, and to be honest it would be a very tough task to make absolutely no mistakes during the process.

That’s the only trick in this game—having all the tools and knowing how and when to use them. Piece of cake, right? Happy holidays from all of us here at SF Guitarworks.