Making a nut is serious business. An otherwise great guitar will suck if the nut isn’t cut properly. Cut too high, and the action will feel stiff and play sharp; cut too low it will buzz on the open strings; if the spacing is too close chords will feel claustrophobic; if the spacing is too wide strings will pull off the sides of the fretboard; if the slots aren’t cut for the proper string sizes, they will not stay in tune or will sound weak.

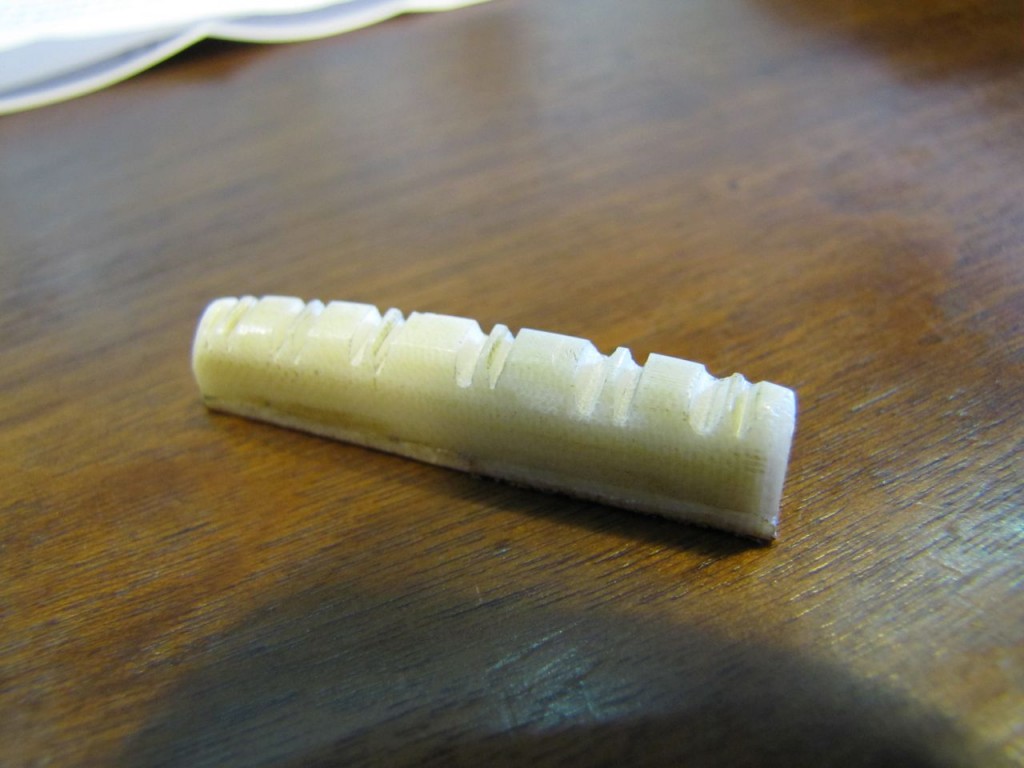

Most guitars straight out of the factory need some level of work on their nuts in order to play properly. Take this Gibson 12-string nut, for example:

We took this out of a vintage Gibson ES-335 12-string. This guitar squeezes an extra six strings onto a standard size neck, so proper spacing is critical. This was the original nut, and it was cut rather poorly: the spacing was all over the place, and it was cut too high, so all the strings felt stiff and were playing sharp. 12-string guitars are hard enough to tune, so if there’s anything even slightly off with the intonation you’ll really hear it!

In addition to refretting this guitar, we also made a new bone nut for it. We use a specialized rule that allows us to set the string spacing across the nut, compensating for the individual string gauges. If we just measured them from the center of each string, the bass strings would be closer to each other than the trebles, since they’re of a thicker gauge. 12-string spacing is tricky – the strings can’t be too close together, or they’ll rattle against each other; too far apart and it will be difficult to fret.

Our tech Aaron made this new nut. Nice, huh?