Leveling and crowning the frets during a fret job is only half the story. Each fret needs to be buffed and polished – which is sometimes the most time consuming part of the gig. Each fret is buffed with super fine, then ultrafine sanding sponges, then with 0000 steel wool, and finally polished with a dremel tool with a polishing wheel and buffing compound. It’s important to buff the frets to a mirror shine – and it’s not just for looks. A perfectly polished fret is easier to bend strings on, allowing the string to smoothly slide across the fret.

Doing this on an instrument with a maple fingerboard requires quite a bit more work than one with a rosewood or ebony board. Most maple necks have a finish on the board (some polyurethane, some nitrocellulose), and extra care needs to be taken to protect them during fretwork.

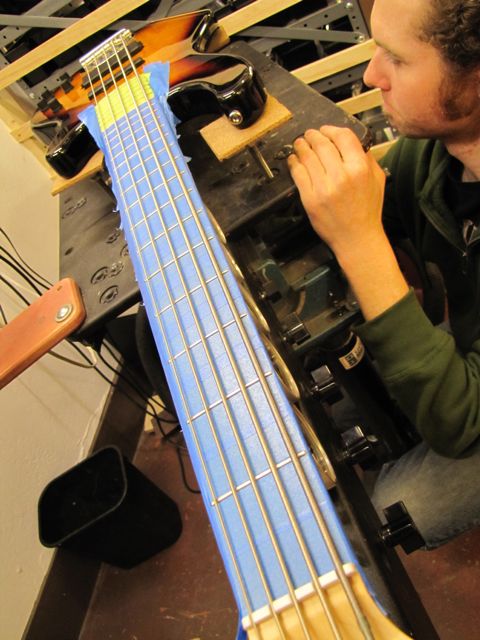

We always tape the instrument before we do the fretwork, to protect the board during the leveling and crowning process. On unfinished boards, we can simply tape them up, but on finished fingerboards, we wax the board and de-tack the tape to prevent the tape from damaging the finish. It’s time consuming, and we chew through miles and miles of tape – but it’s important to do the job right.

It’s instruments like this that should earn us an endorsement deal from 3M Scotch tapes:

And here’s a good example of why we tape them up – the polishing wheel spins pretty fast, and would damage the board if the tape wasn’t there to protect it:

The final result:

And that’s how it’s done.